Failed 3D prints are a natural part of the process, often due to clogged nozzles, bed adhesion issues, or slicing errors. Instead of tossing them out, I've started finding ways to repurpose these leftovers into handy tools for my home and workspace. It's become a satisfying habit that not only saves plastic from the landfill but also adds function where I least expected it. Here are some real-life examples of how I've transformed broken or unfinished prints into something useful.

Related

11 household tools and gadgets you can 3D print instead of buying

Your 3D printer is useful for more than toys and fidgets. Here are some household tools and gadgets you can print instead of purchase

5 Makeshift hooks and hangers

Broken parts become quick, wall-mounted helpers

I ended up with several failed hook prints that snapped or stopped early due to issues with the filament. Even though the tops were incomplete, the bases were still strong and flat enough to mount with double-sided tape or screws. I started placing them near my 3D printer, on the side of cabinets, and by my desk. They're now holding cables, scissors, face masks, and keys without a problem.

Some warped or broken hook prints made good corner guides or hangers when flipped or trimmed. One became a sturdy cable guide behind my monitor just by screwing it in sideways. Another now supports the USB hub under my desk. These prints didn't serve their original purpose, but they still offered structure where I needed it.

I've even used half-printed hooks on the inside of cabinet doors. By stacking two together or backing them with scrap wood, I created a quick hanger for measuring spoons and light brushes. When something breaks off or fails to complete, I've learned to examine the shape and determine where it might still be helpful. It's all about thinking in terms of form and function, not just perfection.

4 Drawer dividers from print leftovers

Misshapen prints still help stay organized

While printing a batch of desk drawer trays, my printer jammed halfway through multiple jobs. Instead of tossing the warped pieces, I tested how they fit in various drawers. Many of them slid perfectly into place and became easy dividers for pens, memory cards, and USB drives. I didn't even need to send most of them; I just dropped them in.

In my kitchen, one curled coaster became a perfect separator between batteries and spare lighters in a junk drawer. Another leftover became a low-profile tray for rubber bands. These pieces might not have matched in height or color, but they brought order to places that were previously cluttered. A failed print doesn't have to be pretty to be helpful.

I also stacked similar scrubs together, using hot glue from deeper dividers. That worked well for organizing small tools and bits in my 3D printing drawer. Instead of starting a new design every time I wanted an organizer, I learned to dig through my failed print bin first. Often, the solution is already there, just waiting to be repurposed.

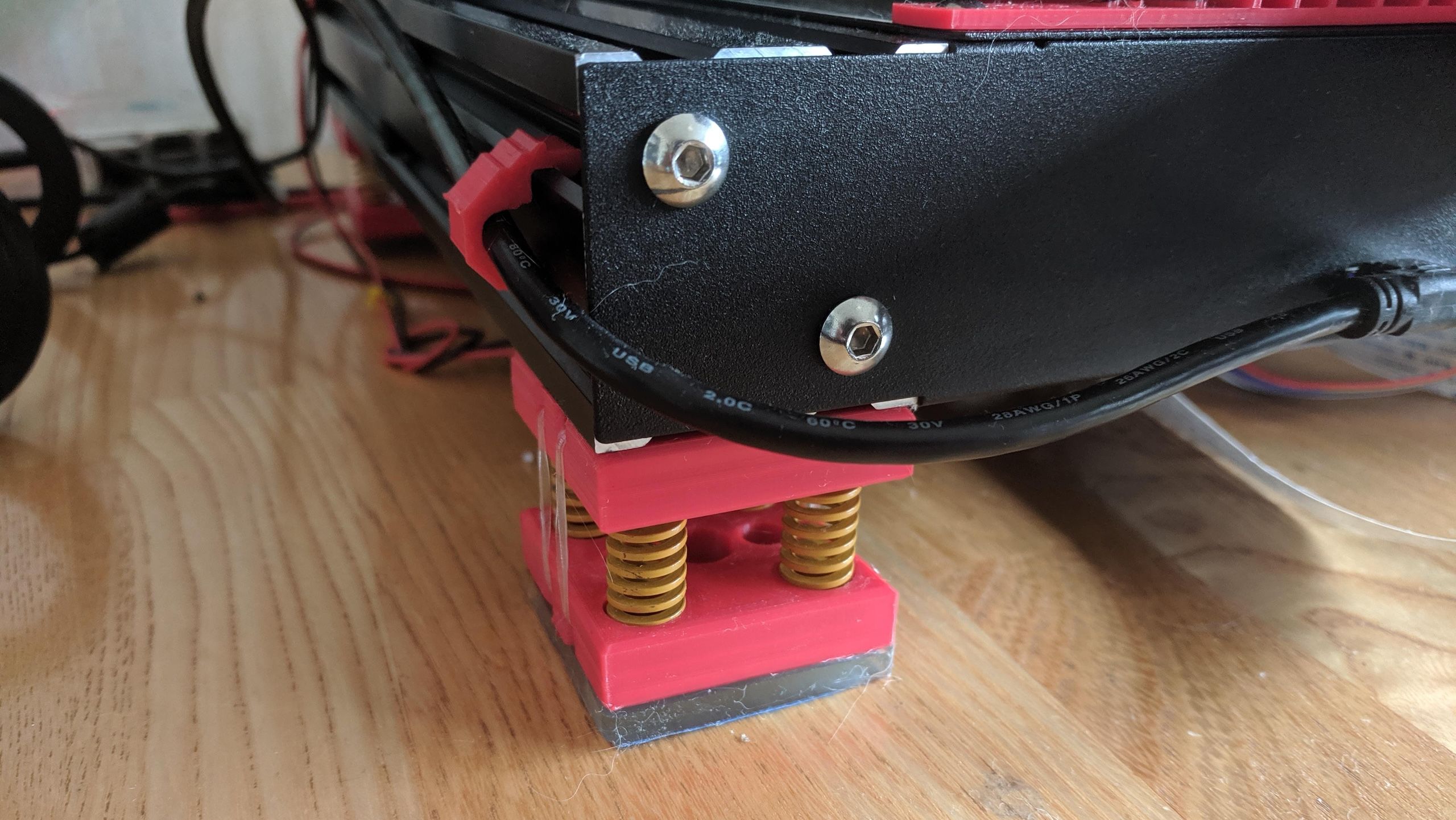

3 Spacers, feet, and vibration dampers

Partial prints cushion my appliances and gear

Source: login721/Reddit

Some of my favorite reuse tricks came from failed TPU and PETG prints. They had enough structure to work as bumpers, feet, or spacers under noisy machines and electronics. I cut larger scraps into strips and placed them under my resin curing station to reduce rattling. A failed phone stand even became the foot for a lamp that wouldn't sit level.

PLA pieces have also proven useful as nonslip feet. With a bit of rubber cement or padding underneath, they worked great for propping up external drives, speakers, or small furniture. I used jagged edges from broken prints to wedge a loose shelf in place. Not everything needs to be flat or symmetrical to be useful.

For more vibration-sensitive tools, I turned to failed prints with thicker walls or infill-heavy bases. One became a cushion between my desk and monitor mount. Others act as low-profile risers to keep air flowing around a pie cluster. Whether flexible or rigid, these scraps have evolved into practical support tools with minimal extra effort.

2 Scrap parts turned into plant markers

Failed prints found new life in the garden

While cleaning up a stack of flat, failed tags and tokens, I realized they'd be perfect for garden markers. I sanded a few smooth areas, grabbed a Sharpie, and started labeling the herbs in a friend’s garden. They held up in both dirt and planters, even through storms and scorching summer temperatures. My friend says these repurposed failed prints have become his go-to markers for every planting season.

Cracked trays and curled spoons also found uses outdoors. I can use them to scoop potting soil or prop up small pots. A failed coaster acts as a water catch plate for a rosemary plant. It doesn't matter that they're mismatched or warped; in the garden, function always wins.

Because these pieces are already unwanted, I don't worry about them getting dirty or breaking again. Another friend even keeps a tub of odd-shaped scraps (which I refresh monthly) next to her shed just in case she needs something to scrape weeds or stabilize the trellis. They're more useful than I expected and surprisingly long-lasting in the elements.

Failed prints to keep my workbench tidy

Source: Jamboodle/MakerWorld

When a large enclosure print failed at 80%, I was almost going to throw it out. Then I realized it was deep enough to catch screws and cable ties, so I dropped it on my workbench. That one print has become my go-to tray for hotend parts, drill bits, and scrap filament ends. It doesn't look great, but it keeps my tools organized.

Other failed prints have joined it over time. Some were meant to be stackable boxes or drawer inserts, but warped too much to nest properly. I use them as bins under my sink, in my storage closet, and next to my printer to collect debris. Even combined a few with glue to create larger compartments.

Every few weeks, I dig into my scrap bin to see what I can turn into storage. If a piece has decent side walls and is mostly flat-bottomed, I keep it. It's cheaper than printing new containers, and I never worry about losing or damaging them. They served their purpose without needing a second print job.

Every day, usefulness comes from imperfect prints.

I used to get frustrated every time a print failed, and to be honest, I still do. However, now I see these failed prints as potential tools. The most minor parts could become spacers, guides, or storage helpers. Larger failures often solve problems I didn't even know I had. It just takes a little imagination and willingness to experiment. Repurposing a failed print isn't just about saving money or reducing waste; it's also about sustainability. It also adds creativity to my cleanup process and helps me look at prints with fresh eyes.

.png)

English (US) ·

English (US) ·