There are plenty of solid 3D modeling tools out there, but Onshape has carved out a permanent spot in my workflow. After testing a range of design platforms for 3D printing projects, I found Onshape to be the most consistent, flexible, and user-friendly for my needs. It hits the right balance between powerful features and cloud-based convenience. Whether I’m prototyping a Raspberry Pi case or tweaking functional parts for around the house, Onshape helps me get the job done faster and more efficiently.

5 Cloud-based workflow fits how I work

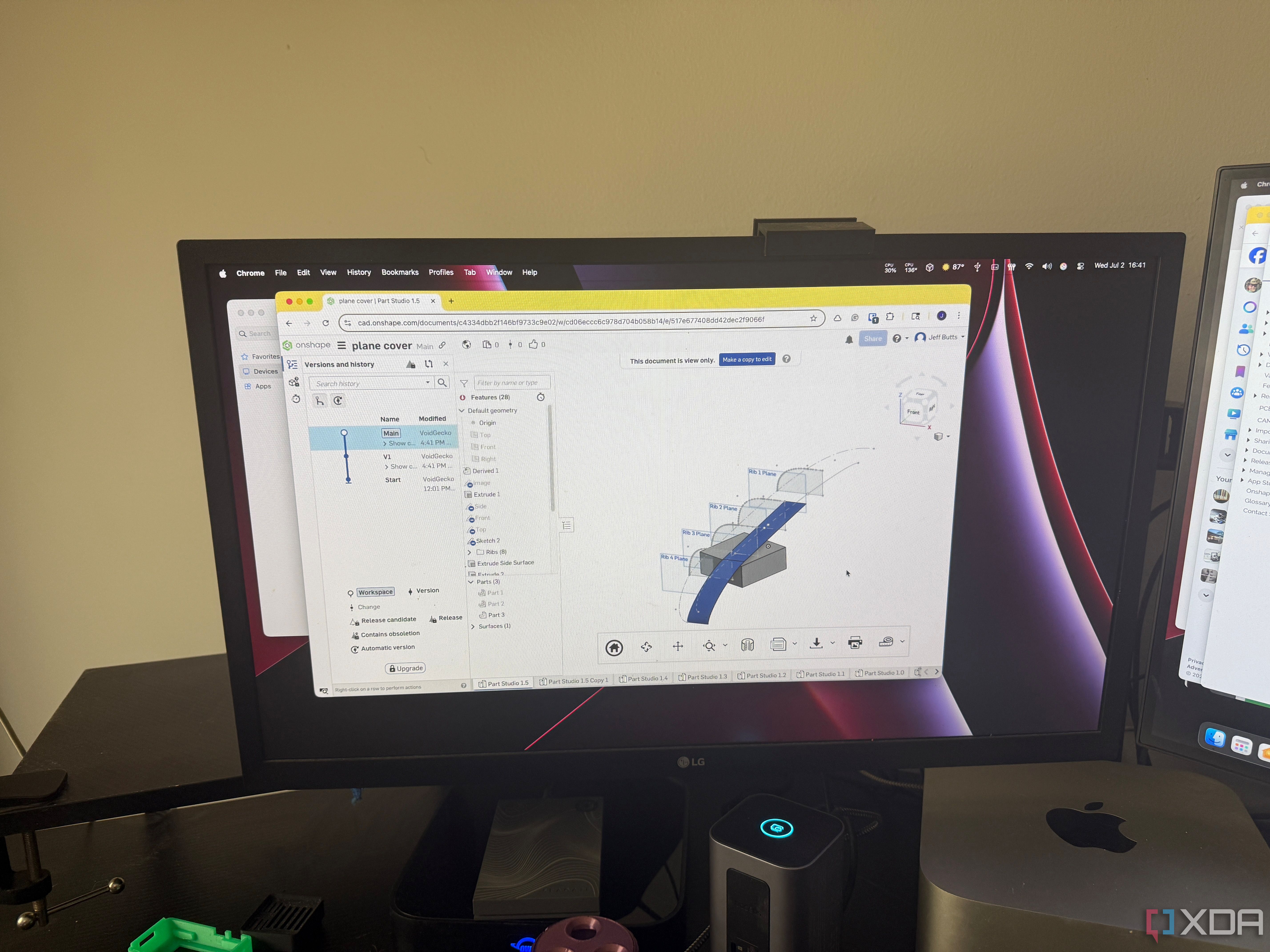

I can design anywhere without installing anything

One of the biggest reasons I've stuck with Onshape is its completely browser-based interface. I can open a design from any computer or even my tablet without worrying about syncing files or installing updates. This also means I can collaborate or review designs with others on the fly, even if they're not using a powerful desktop. As someone who jumps between workstations, that kind of accessibility makes a huge difference.

The cloud-first approach also gives me peace of mind when it comes to version control. Every design change is tracked automatically, and I can always roll back or compare versions when needed. That's especially helpful during iterative design processes, where changes occur frequently and quickly. I don't have to dig through old folders or worry about accidentally overwriting a working file.

Being able to access Onshape from a browser doesn't mean sacrificing performance. The modeling engine runs smoothly, and I rarely encounter lag, even on more complex builds. For a CAD platform that runs without a local install, it still feels like a full-featured desktop tool.

4 A feature set built for precision

Tools and constraints give total modeling control

When designing for 3D printing, accuracy matters. Onshape’s constraint-based sketching and parametric modeling tools give me exact control over dimensions, fit, and tolerances. Whether I'm designing press-fit parts, articulating joints, or simply ensuring wall thickness adheres to specifications, I don't have to guess. The modeling tools are responsive and behave predictively, even when the geometry gets a bit complicated.

I also appreciate the flexibility of Onshape’s feature tree. It's easy to go back and edit earlier steps without breaking downstream geometry. That kind of non-destructive workflow is a lifesaver when refining a print design or adapting a part for a different material. Instead of rebuilding from scratch, I can make targeted changes and keep everything else intact.

Onshape includes plenty of advanced tools, too, like multi-part studios and assemblies, that let me design entire mechanisms in one workspace. It scales with complexity as projects evolve. Whether I'm working on something basic or intricate, I don't feel limited by the tool set.

3 Collaboration is straightforward and effective

Sharing designs is easy, and real-time edits work

Designing an isolation doesn't always work, especially when you're troubleshooting or building off someone else's idea. Onshape makes it simple to share models with others, control their permissions, and even let them edit in real-time. That's especially useful while I'm iterating on a design with a friend or asking for feedback before printing.

Unlike file-based CAD tools, there's no need to send an outdated STL file or juggle email attachments. I can share a link, and collaborators instantly get the latest version. Changes made by others appear live, allowing us to see how updates affect the model. It's a lot like working on a shared document but for precision CAD work.

Onshape also gives full access to thousands of public models made by other users. That's incredibly helpful when I need inspiration, reference, geometry, or just want to see how someone else approached the design problem. I can fork a model, modify it to suit my own needs, or use it as a teaching tool to enhance my own skills. The openness of that library makes collaboration feel bigger than just one team. Instead, it's actually the whole Onshape community.

2 Integrations and exports work smoothly.

Onshape pays nicely with slicers and other tools.

After modeling, I need to get files into my slicer without a hitch. Onshape makes that part simple. Exporting as STL, STEP, or even DXF formats is quick, and the output is clean. I've never had a model choke in Cura or Orca Slicer due to weird geometry from Onshape exports. That reliability means fewer print failures and less time wasted.

I also use Onshape, alongside a few plug-ins and external tools, that help with mechanical analysis and layout planning. Since it supports standard formats and includes API access, Onshape seamlessly integrates into a larger workflow. I don't feel like I'm locked into a walled garden. Everything connects smoothly from start to finish.

For repeatable prints or evolving designs, I can even use configurations to generate multiple variations of a model with just a few parameters. That has saved me hours when testing for intolerances or creating sets of parts that differ only slightly. The workflow from design to print stays lean and efficient.

1 The free plan is perfect for my needs.

Hobbyist access without a hefty price tag.

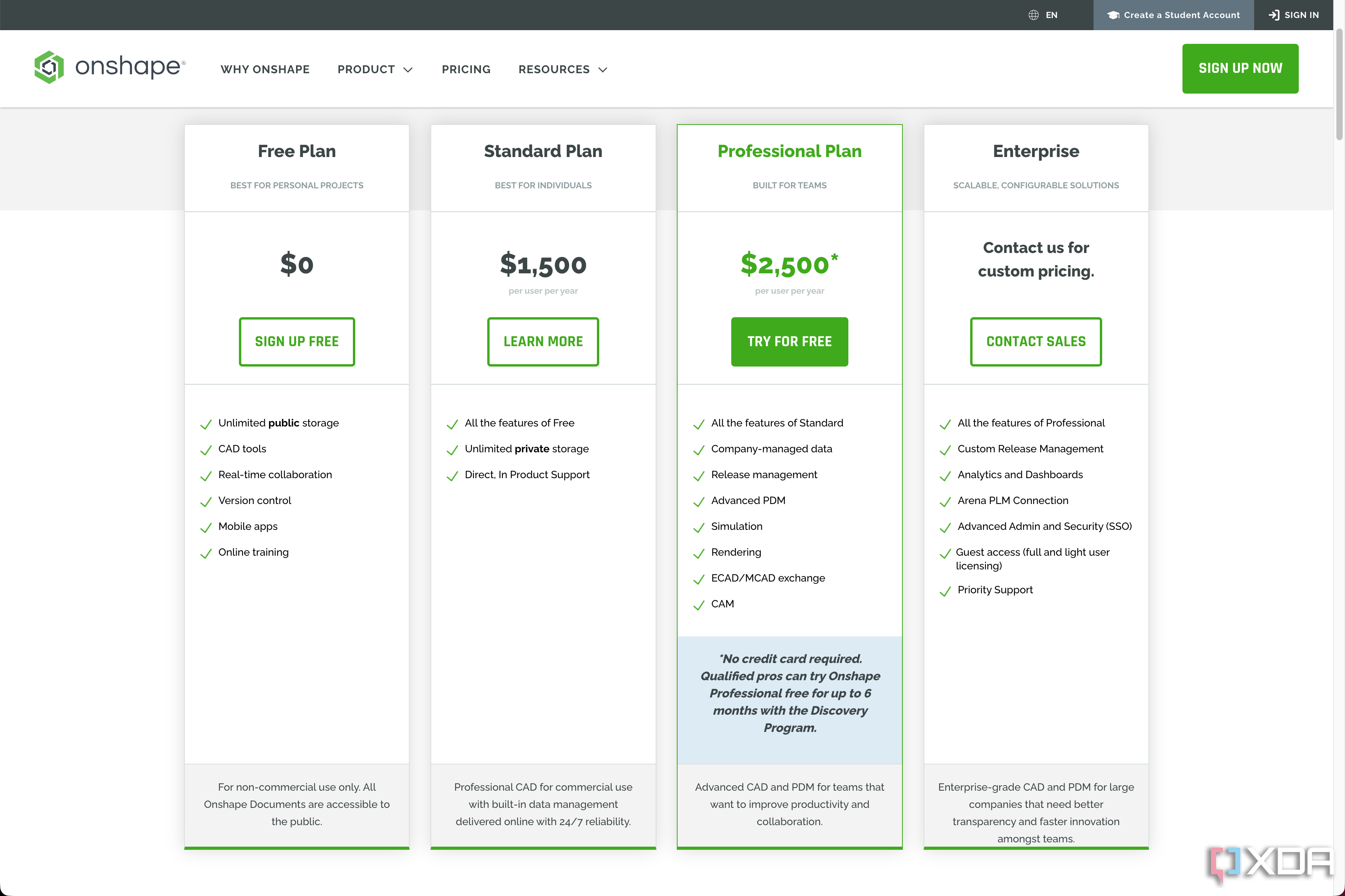

For all the features Onshape offers, the free plan is surprisingly generous. As long as I don't need private designs, I can create as many public models as I want, with access to almost the complete feature set. That's more than enough for hobbyist 3D printing work, especially if I'm planning to share designs anyway. I don't feel pressured to upgrade just to get the basics done.

Even the limitations make sense. Public models encourage reuse and community sharing, which I'm already doing through platforms like Printable and MakerWorld. Being able to point someone to an Onshape link instead of uploading an STL also helps when I want to show how a model is constructed. It keeps my design thinking transparent.

If I ever move into more commercial work, upgrading is straightforward. The transition from free to pro doesn't mean switching tools or losing anything I've already made. That long-term flexibility is one more reason I'm happy to keep Onshape in my toolkit.

A tool that keeps delivering where it matters most.

Sticking with Onshape has made my 3D printing projects more organized, more precise, and more collaborative. It fits right into my workflow and doesn't get in the way when I'm trying to iterate quickly. Whether I'm modeling functional parts or creative prints, the platform keeps things smooth and consistent. As long as it keeps working this well, I have no reason to switch.

.png)

English (US) ·

English (US) ·