Sign in to your XDA account

Summary

- 3D prints have unique "fingerprints" that allow the identification of individual machines, even those of the same model.

- University of Illinois researchers, led by Bill King, created an AI system that can identify machine prints with 98% accuracy.

- There's the potential to trace poor quality products back to the machine that printed them, improving larger-scale manufacturing processes.

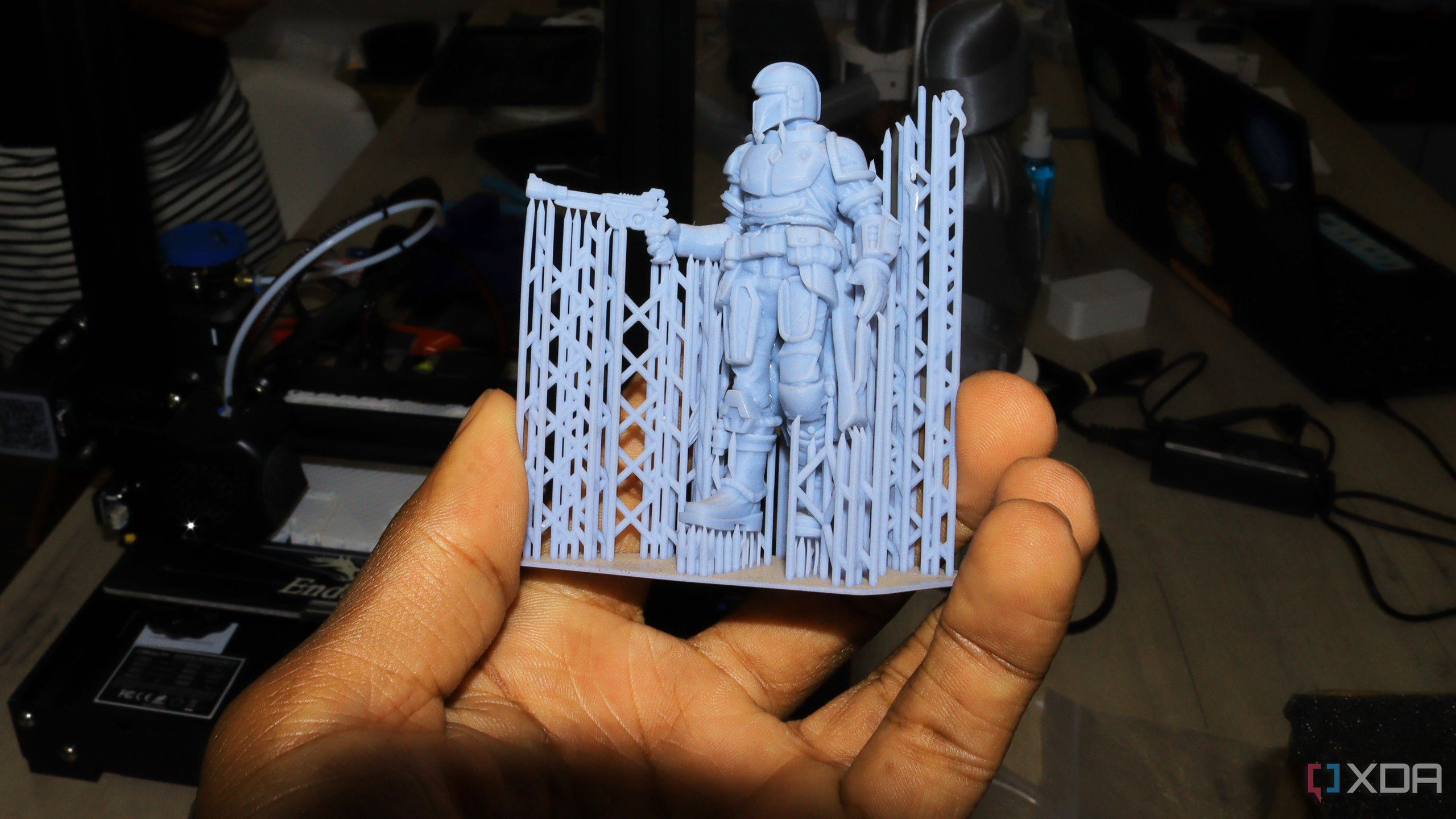

If someone 3D printed an object and handed it to you, how confident would you be in your ability to tell exactly what model of 3D printer made it? I don't know about you, but I would have zero chance at identifying what machine made it without random guessing.

Well, it turns out that every print has a unique "fingerprint" that allows someone to trace it back to the machine that made it. And we're not just talking about which model made it; we're talking about which exact individual machine made which individual prints, even if each machine was the same printer model.

University of Illinois researchers discover 3D printer "fingerprints" that can identify a specific machine

As Notebook Check spotted, University of Illinois researchers found a reliable way to match a 3D print to the exact machine that made it. The researcher team was headed by Bill King, aprofessor of mechanical science and engineering at the University of Illinois, Urbana-Champaign. Once King made the discovery, they created an AI system that could analyze and identify which machine made which component.

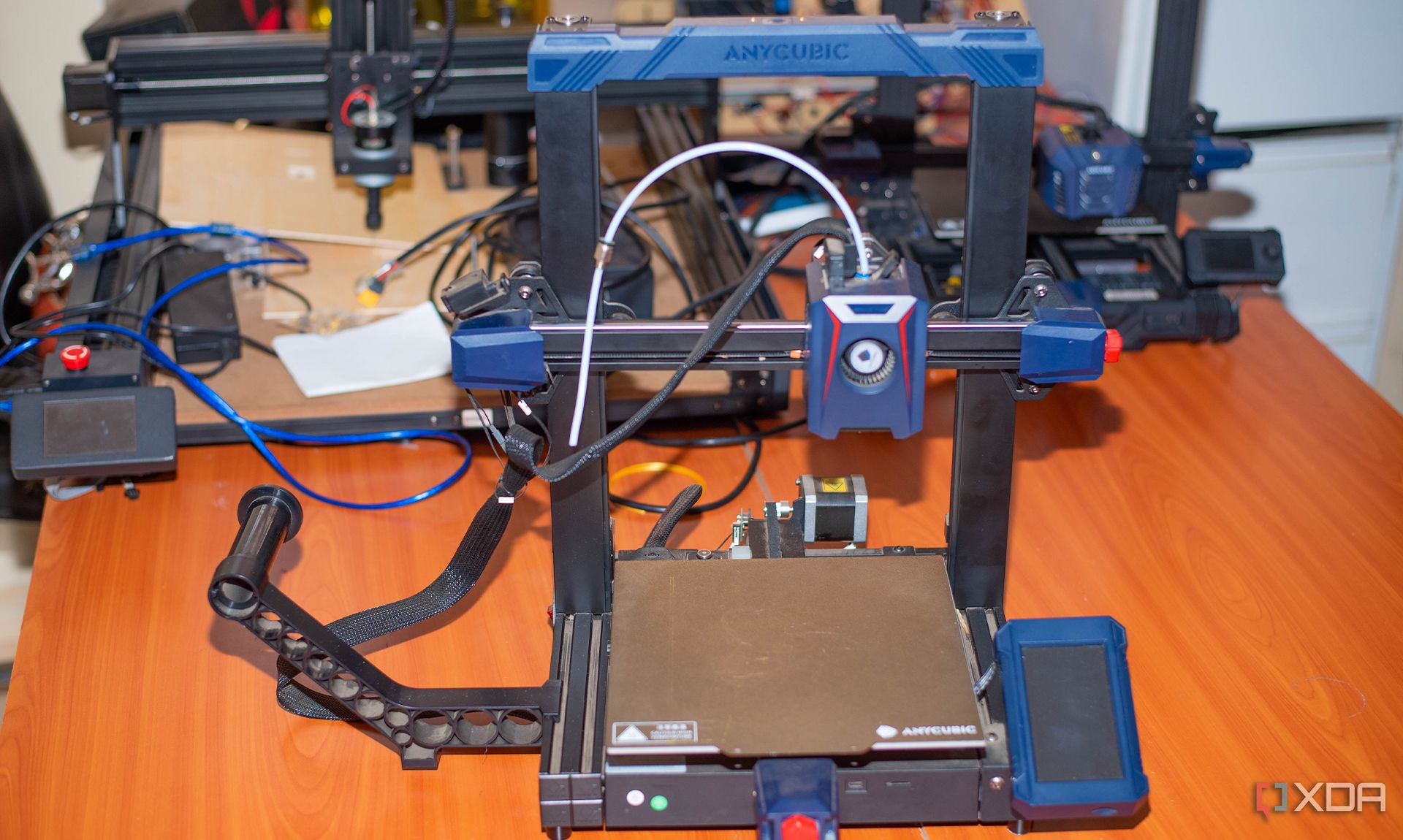

To create the AI model, the team fed it 9,192 photographs of parts. These parts were printed on 21 machines, which were collectively built by six brands and with four different fabrication processes. The team then gave the AI an image of a square millimeter of a printed part, and it managed to pin the print to the machine with 98% accuracy.

Surprised? You have every right to be. In fact, even King themselves can't quite believe it:

“We are still amazed that this works: we can print the same part design on two identical machines –same model, same process settings, same material – and each machine leaves a unique fingerprint that the AI model can trace back to the machine,” King said. “It’s possible to determine exactly where and how something was made. You don’t have to take your supplier’s word on anything.”

King believes the tech could be pushed even further, with the AI developing an accurate reading after just 10 scans of parts printed from a machine. King believes this research would make it a lot easier for people to figure out where something went wrong in larger-scale product manufacturing processes. If a particular product's build quality is poor, people can quickly trace the 3D print back to the very machine that made it, making it easy to report "bad eggs" in the production chain.

.png)

English (US) ·

English (US) ·