Sign in to your XDA account

Summary

- MIT scientists created a way to 3D print glass-like structures without extreme temperatures.

- The special mixture used provides good structural integrity and diverse design possibilities.

- Researchers are focused on enhancing the optical clarity of the glass for various applications.

I think it's the dream of every 3D printer enthusiast to gain the ability to 3D print anything they want. Want a new computer? Perhaps a new house? Maybe a steak dinner? Get it 3D printed. Of course, we are decades away from having everything at the end of a 3D printer's nozzle, but we're making some excellent progress.

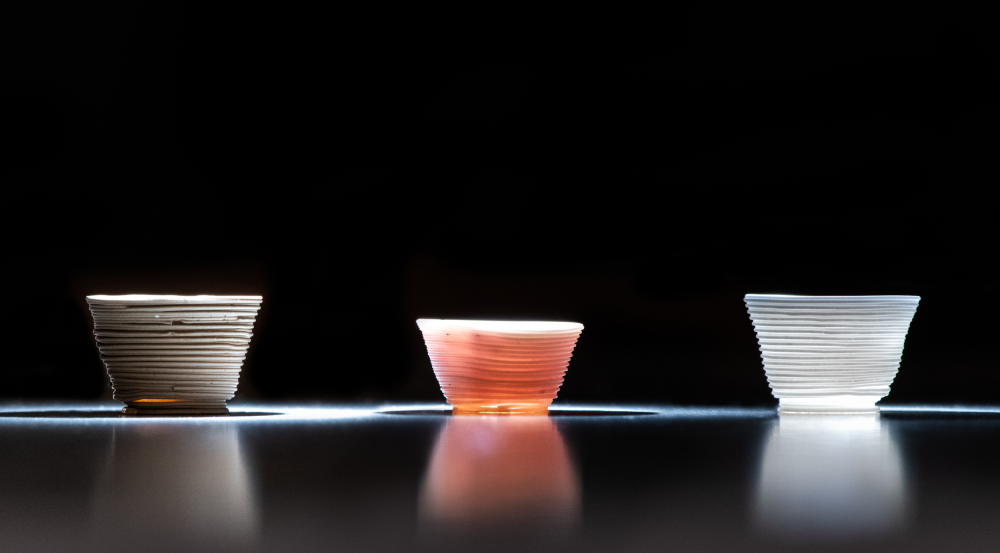

For example, take these scientists that managed to figure out a medium that allows people to 3D print something that looks and feels very much like glass. And while it may not be 100% the 'real deal', its unique circumstances allow people to create glass structures that could otherwise not exist.

Related

You simply have to see these 5 weird and wacky 3D printing experiments

You've seen the 3D printed tools, toys, and fidgets, but these wild 3D printing experiments are like something out of science fiction

Researchers from MIT figure out how to 3D print glass-like structures

As spotted by Hackaday, scientists from the Massachussets Institute of Technology (MIT) created a post on the Lincoln Laboratory website describing what they've achieved with their latest research. As the researchers explain, they're very interested in getting 3D printers to create glass structures; however, it turns out the process is a lot trickier than simply stuffing a mixture into your printer's nozzle:

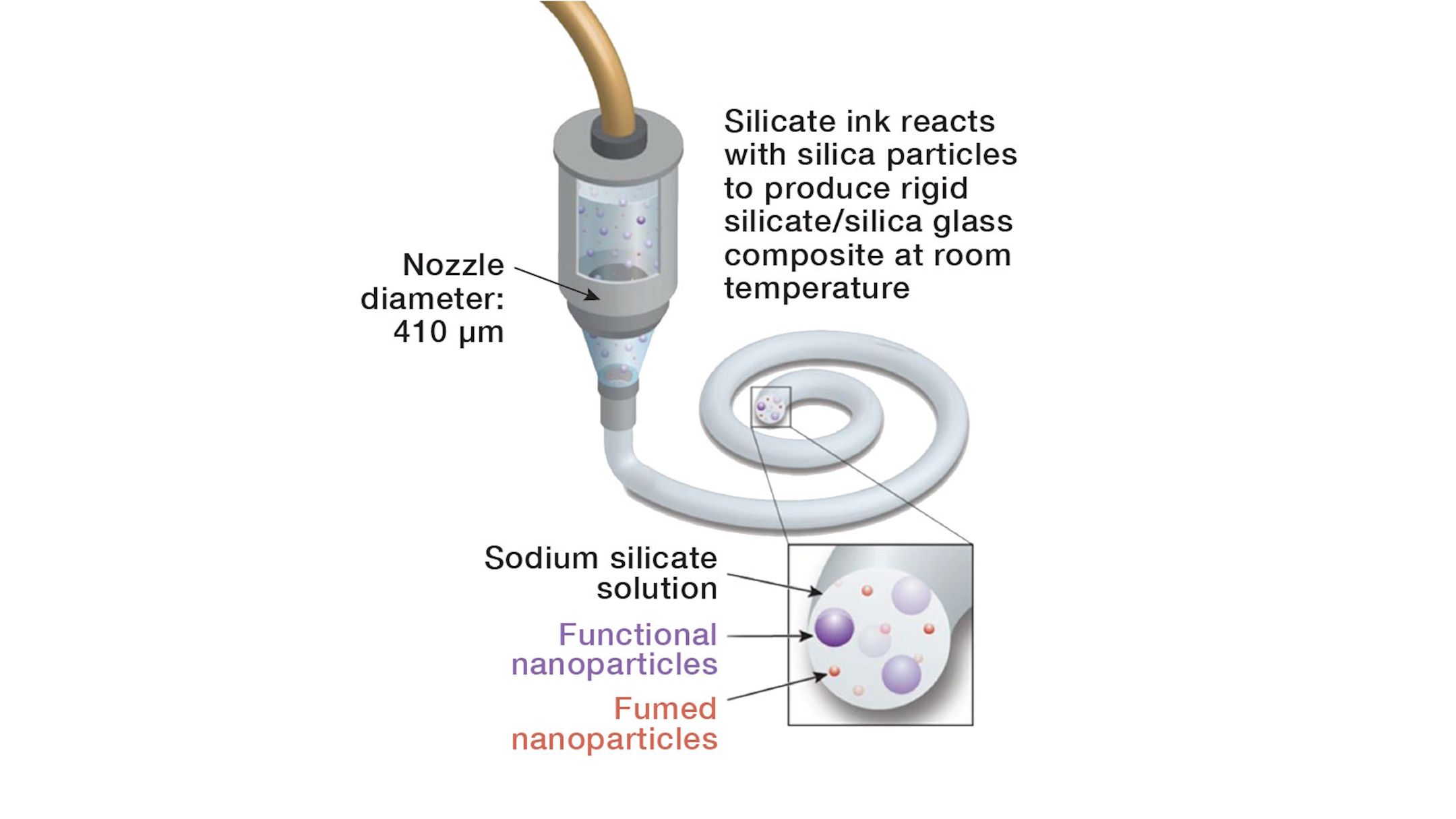

Using inorganic composite glasses solves many of the instability issues and offers a promising approach to create structures with diverse shapes and properties. However, the high temperatures (greater than 1,000°C) typically used to sinter (harden) glass items have hindered the use of glass in 3D printing. High-temperature processing requires specialized equipment and is incompatible with temperature-sensitive materials and components.

The solution was to combine sodium silicate (also known as "water glass") with "nanoparticles of other inorganics" to create a similar glass-like effect but without all of the issues with blasting stuff at over 1,000°C. In fact, the researchers managed to get results by heating it to 250°C, which is far more manageable for a 3D printing system.

Right now, the researchers note that using this special mixture allows them to 3D print designs that you can't achieve with typical glass-making techniques. The mixture also has good structural integrity, withstands heat well, and doesn't shrink too badly. However, the researchers aren't done yet; they're hard at work finding the perfect combination to improve the "optical clarity" of the glass, as well as discovering different inks that respond to chemicals and electricity in different ways for a range of applications.

So, it may be a while until you can drink out of the glass stein you just 3D printed, but honestly, if this discovery makes it to market, I can see it being a huge boon for hobbyists. It doesn't seem that the materials and equipment needed to make 3D printed glass structures are that unobtainable for someone passionate about their project. While we wait, check out these methods of finding new projects to print.

.png)

English (US) ·

English (US) ·