Summary

- Always choose 3D printing over buying pre-built products for the learning experience and satisfaction.

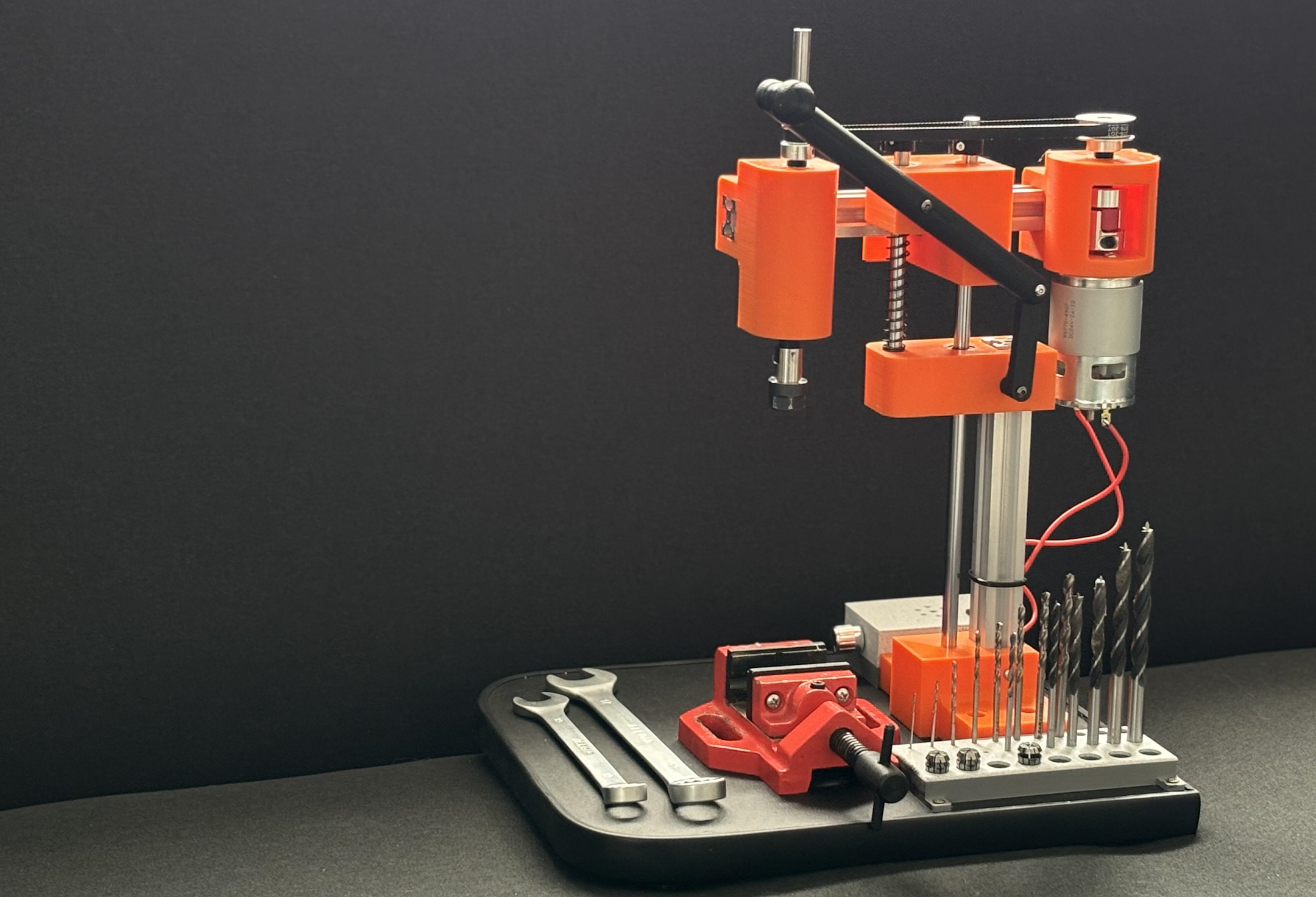

- A DIY drill press project showcases creativity and allows for customization, though it is considered "overkill."

- The drill press project, costing $44.50, proves affordable, but durability under stress remains untested.

Sometimes, you just have to 3D print something that you could otherwise buy, just for the sakes of building it. Even if the end process is a little more convoluted and takes more patience than simply finding the target product on Amazon and clicking the "Buy Now" button, you still learn a lot, get that satisfaction of making something, and have all the knowledge and equipment to repair it if something breaks.

If you're someone who enjoys building for building's sake, you'll like this 3D printing project that creates a drill press from scratch. You'll need a few extra parts, of course, and even the creator called the idea "overkill," but if you're itching to make something, it sounds like a fun project to me.

Related

I try to convince everyone to get into 3D printing, and these are the 4 reasons I think you should

After 3D printing for several years, I recommend that anyone buy a 3D printer for the following four main reasons.

This 3D-printed drill press puts the "why" in "why not"

As spotted by Tom's Hardware, the story starts when someone posted a thread showing off their DIY drill press on the 3D Printing subreddit. As you might imagine, people got really interested in how they managed to get everything working and asked if the original poster could share their methods.

In a reply, the original poster explained how they made it:

I hadn't plan it as "mass market" model, but mostly as inspiration for other. So there are no exact parts and instruction.

Anyway. Here is stl https://github.com/DCSets/drill-press/blob/main/Drill%20v13.stl (split it by objects) and 3d model https://a360.co/3HAPs8Z

They then linked to the following YouTube video, where they explained the process of making a drill set and all the obstacles they had to overcome to get it done.

Honestly, even if you never intend to actually print this project off, the video is a fascinating watch. DC Sets breaks down what was needed to get everything working and shows the project slowly coming to life. At the end of the video, they reveal that they spent a cool $44.50 getting the project up and running, which is a pretty agreeable price for such a project. However, because the drill is still relatively new, they haven't given it the test runs it deserves before it could be regarded as a home run win. After all, with all the moving parts and the force required for drilling, it'll be interesting to see how the 3D-printed components hold up to the stress.

If this got you into a 3D printing mood, but you're pretty sure you're not up to the task of making an entire drill press, don't fret. You can try something a lot simpler, such as these things you can 3D print that are actually useful. Or, if you like the idea of printing things out instead of buying them new, you can take a look at these everyday items you may no longer have to buy thanks to 3D printing.

.png)

English (US) ·

English (US) ·